The historical origin of brick machine.

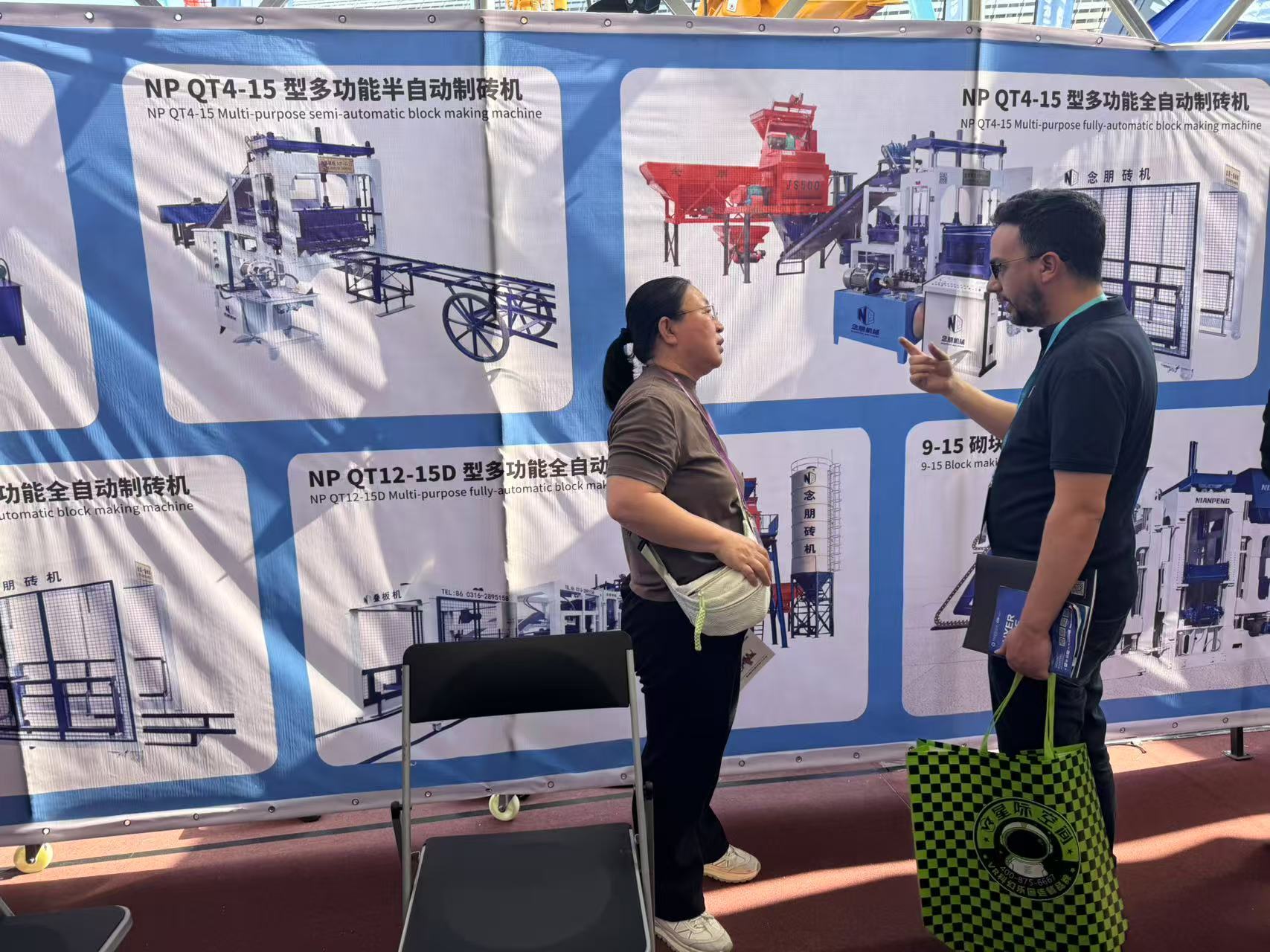

In the new year, China's brick-making machine industry can be described as "a spark can start a prairie fire", brick-making machine equipment can effectively use fly ash, slag, and even industrial waste, recycle, and continue to make contributions to the country and the people. Its environmental protection and energy saving, the new wall material has been affirmed by the state. China's brick machine has been exported to foreign countries, Algeria, Seychelles, the Middle East countries have their healthy figure. It has built a bridge for the brick industry between countries. It has made great contributions to the friendly relations between countries.

There are 120,000 brick and tile enterprises in China, covering more than 6,000 hectares, taking 1.43 billion cubic meters of soil and destroying 1.2 million fields of land. Their energy consumption is about 60 million tons of standard coal per year. The annual energy consumption of the brick-making machine for wall material production and heating in the North accounts for more than 15% of the total annual energy consumption in China. In addition, 170 million tons of carbon dioxide are emitted annually in the production of sintered clay brick, which aggravates the formation of acid rain and greenhouse effect in cities. The transformation of the national wall requires that clay bricks be banned in all cities throughout the country in 2010 and that sintered brick projects be strictly restricted. The birth of fully automatic hydraulic molding machine provides equipment guarantee for the full automatic batch production of non-burning bricks. At the end of the 20th century and the beginning of the 21st century, the production line of non-burning brick with imported foreign equipment began to appear in China. With the success of the research and development of the domestic full-automatic hydraulic molding machine, a large number of production lines of non-burning brick using industrial waste began to appear in China.

Keyword:

86

86