Highlights of Nianpeng brick making machine at the Canton Fair

At the Canton Fair, a globally renowned trade event, Nianpeng Machinery's brick-making machines, with their superior quality and cutting-edge technology, became the center of attention, attracting attention from around the world.

1. Intelligent and Efficient, Leading a New Trend in Production

Automated Production Process: Nianpeng's brick-making machines are equipped with advanced intelligent control systems, automating the entire process, from precise raw material mixing to pressure and vibration frequency control during the molding process, to the automatic conveying and stacking of finished bricks. Operators simply input commands into the central control console for the equipment to operate accurately, significantly reducing manual intervention and labor costs while significantly improving production efficiency. Compared to traditional brick-making equipment, efficiency increases of up to [X]% are achieved.

2. Flexible Brick Type Switching: To meet the diverse demands of the construction market, our brick-making machines can easily and quickly switch between various brick types. Whether it's standard building bricks, special-shaped bricks for landscaping, permeable bricks, or hollow bricks for specialized construction needs, simply replace the corresponding mold and adjust the parameters in the control system, and the equipment can quickly produce products that meet the requirements. This truly enables a single machine for multiple uses, providing customers with a comprehensive brick production solution.

II. Environmental Pioneer, Practicing Green Development

1. Waste Recycling: Responding to global environmental concerns, the Nianpeng brick making machine boasts a wide range of raw material adaptability, utilizing industrial waste (such as slag and fly ash), construction waste (crushed concrete blocks and bricks), and tailings sand as primary raw materials. Through specialized formulations and process engineering, these once environmental burdens are transformed into high-strength, high-quality building bricks, effectively reducing reliance on natural resource extraction and providing for the rational disposal of waste.

2. It opens up new avenues, helping the construction industry move towards green and sustainable development.

Energy-saving and Emission-Reducing Design: The Nianpeng brick making machine utilizes a new energy-saving power system, combined with an optimized mechanical transmission structure, significantly reducing energy consumption. Furthermore, it is equipped with an intelligent energy management system that monitors the energy consumption of each component in real time and automatically adjusts power output based on production conditions, achieving efficient energy utilization. Compared to similar products, energy consumption is reduced by up to [X]%. Furthermore, noise and dust pollution generated during operation are effectively controlled, creating a more environmentally friendly working environment for the production workshop and surrounding environment.

III. Superior Quality, Setting an Industry Benchmark

1. Sturdy and Durable Construction: The main structure of the brick making machine is constructed of high-quality, high-strength steel, undergoing precision machining and rigorous welding processes to ensure exceptional stability and deformation resistance. Key components, such as the vibrating table and mold frame, are made from special alloys and heat-treated to enhance their hardness and wear resistance. They can withstand long-term, high-intensity production operations, effectively extending the equipment's service life and reducing maintenance frequency and costs.

2. Precise and Stable Molding Technology: The machine utilizes a combination of advanced vibration molding technology and hydraulic pressing. During the molding process, precise control of vibration frequency, amplitude, and pressing pressure ensures a densely packed internal brick particle structure, resulting in bricks of exceptional strength and stability. Tests conducted by professional testing institutions have shown that key performance indicators such as compressive strength and flexural strength of bricks produced by our brick making machine far exceed industry standards, meeting the demands of various high-standard construction projects.

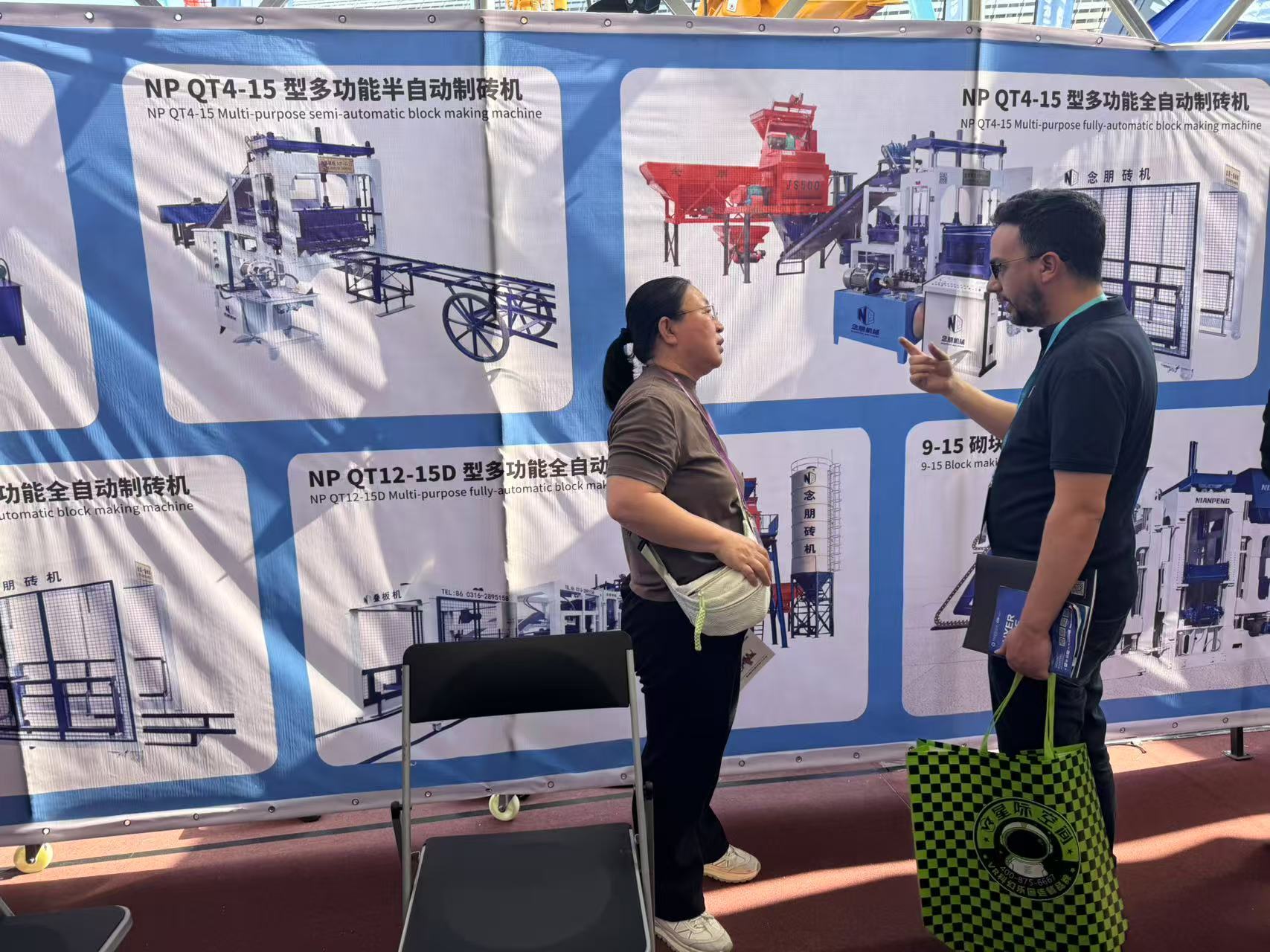

IV. Remarkable Results at the Canton Fair

At the Canton Fair, our brick-making machines attracted a large number of buyers, builders, and industry experts from around the world to visit and inquire. Many international customers expressed strong interest in the equipment, and through on-site demonstrations and technical explanations, they gained a deep understanding of its advantages and features. During the exhibition, we reached cooperation agreements with several companies from [specific countries and regions] and signed several large orders. We also engaged in in-depth exchanges and discussions with international peers, absorbing valuable industry experience and cutting-edge technological concepts, further enhancing the competitiveness and influence of our products in the international market.

Choosing our brick-making machines, which shone brightly at the Canton Fair, means choosing an efficient, environmentally friendly, and high-quality brick production solution, and working together to create a bright future for the construction industry.

Keyword: Fully automatic brick machine,Brick Machine,cement brick machine,Hollow brick machine,Brick machine equipment manufacturers

86

86